Would you eat off a dirty plate? Would you chop your food with a rusty knife? Or would you eat something sitting in your fridge for way too long that is now full of mold?

Probably not.

If you want to jeopardize your draft beer’s quality, taste, and freshness, the fastest way to do that is with dirty draft beer lines and beer faucets.

After all, beer is technically food. This means that lots of stuff can grow and collect inside your beer lines and faucets (like yeast, mold, bacteria) when they aren’t cleaned regularly.

Brewers devote so much time, effort, and resources to deliver the best possible beer for consumers (all of us). From ingredient selection to technological advances in brewing, so much love goes into producing our favorite carbonated beverages.

Clean beer lines are vital to maintaining the quality of draft beer and other beverage products. Most batches of beer are tested throughout the brewing process to ensure consistency and quality from keg to keg.

Let’s protect the quality and flavor of your beer, protect the health of your customers, and make your entire draft beer system last longer.

The small investment in beer line cleaning and your draft system components will maximize your profits and fresh, flavorful beer pour after pour.

Here are our draft system cleaning & service recommendations that you can use to do a survey and determine: how clean is your draft beer system?

Our Draft System Cleaning and Service Recommendations

Let’s begin with what needs to be happening for your draft beer line cleanings and the frequencies of these services.

The following list is based on the Brewer’s Associations’ Draught System Cleaning and Service Recommendations, however our standards at Draft Beer Intelligence exceed these. Therefore, the following list is a combination of both:

These guidelines reflect the key actions needed to maintain a clean draft system that will dispense trouble-free, high-quality beer.

Draft Line Cleaning: Minimum Every Two Weeks (14 days)

- Clearly posted documentation of line cleaning and servicing records is recommended in all keg coolers.

- Push beer from the lines with warm water.

- Clean lines with 2% caustic solution for routine cleaning of well-maintained lines, or with 3% caustic solution for older or more problematic lines. Contact your chemical manufacturer to determine how much chemical is needed to achieve these recommended concentrations. If you use non-caustic-based cleaners, such as acid- or silicate-based cleaners, be sure to use the cleaning concentrations recommended by the manufacturer. For best results, maintain the cleaning solution temperature between 80°F and 110°F during the cleaning process.

- Using an electric pump, a caustic solution should be circulated through the lines for a minimum of 15 minutes at a steady flow rate that ideally exceeds the flow rate of the beer. If a pressurized cleaning canister is used (though not recommended), the solution needs to be left standing in the lines for no less than 20 minutes before purging with clean water.

- Disassemble, service, and hand-clean faucets; hand-clean couplers.

- After cleaning, flush lines with cool fresh water until pH matches that of your tap water and no visible debris is carried from the beer lines.

Acid Cleaning: Every Quarter (Three Months)

- Acid cleanings should be in addition to caustic cleanings, not as a replacement.

- Push beer or caustic cleaner from lines with warm water.

- Clean lines with acid line-cleaner chemical mixed to manufacturer’s guidelines. Maintain a solution temperature of 80-110°F.

- Circulate the acid solution through the lines for 15 minutes at a steady flow rate that ideally exceeds the flow rate of the beer. If a pressurized cleaning canister is used (though not recommended), the solution needs to be left standing in the lines for no less than 20 minutes before purging with clean water. After acid cleaning, flush lines with cool fresh water until the pH matches that of your tap water and no visible debris is carried from the lines.

Hardware Cleaning: Every Quarter (Three Months)

- Disassemble, service, and hand-clean all FOB devices (a.k.a. beer savers, foam detectors).

- Disassemble, service, and hand-clean all couplers.

So – how clean is your draft beer system?

Now that you know what should be happening in your building…let’s survey your system to see how clean it really is.

Begin by taking a tour of your beer system components, storage, or take apart a beer faucet to verify cleanliness. Is your draft beer line or draft system cleaning performed on a regular 14-day interval?

Beyond the lines, are the couplers, faucets, exposed shank surfaces, and FOBs being cleaned manually at each line cleaning?

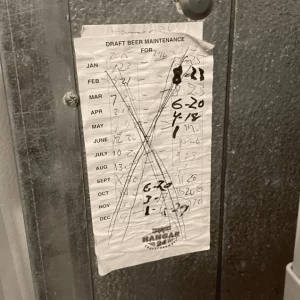

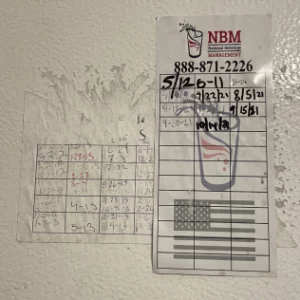

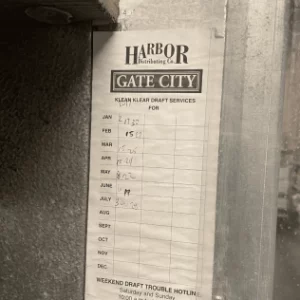

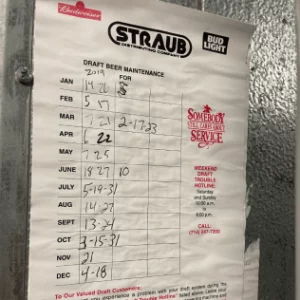

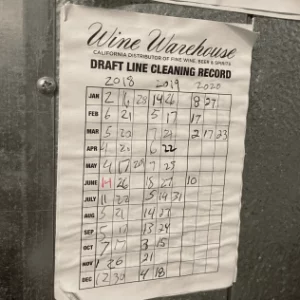

Do your current cleaning logs look like this?

These photos showcase a lack of proper service and document that the beer distributors poorly manage and execute draft beer line cleaning. If adequate cleaning occurs every two (2) weeks, how could one of these logs fit one year’s worth of cleanings? That’s twenty-six (26) cleanings per year.

Which beer lines were cleaned and when? What cleaning protocols were used? Who completed the work, and who reviewed it? You need to know the answers to these questions to deliver fresh tasting beer to your customers.

Do your current beer line cleaning vendor use the proper specifications?

Does your beer line cleaning vendor use cleaning chemicals at the “manufacturer recommended” specifications:

- Proper cleaning chemical mix ratio(s)

- Proper water temperature

- Adequate contact time for the cleaning solution

- Do they thoroughly rinse the draft system lines pre and post-cleaning with water? Flushing beer lines with beer is unacceptable and exposes the customer to cleaning chemicals in their beer.

What cleaning procedures are currently taking place for your draft system?

Do your beer system lines receive a static clean (simple chemical soak)? Or do you receive mechanical clean (turbulent flow-based chemical cleaning loop)?

Do they follow the recommended cleaning time of twenty (20) minutes for a static cleaning? Fifteen (15) minutes for a mechanical cleaning?

How does the beer taste after the line cleaning (if correctly completed)? Does it taste better, the same, or worse?

Questions to ask your beer distributors or beer line cleaning company:

Take a tour of your beer system components storage, or take apart a beer faucet to verify cleanliness. Then, please ask your beer line cleaning company or the beer distributor managing your account for a clear scope of work?

Are they cleaning your beer lines properly and often enough? Then compare what they provide you with all the information above and identify any areas of opportunity that need to be corrected.

What did you find during your survey? Is there room for improvement? If food was served from your lines + faucets, would you eat it?

Here at Draft Beer Intelligence, our standards and commitment revolve around you; the brewers, restaurants, bars, hospitality, and consumers. Clean beer lines will ensure the appearance, aroma, and flavor experience intended by the brewer is delivered pint after pint.

So, let’s give your customers a reason to keep coming back! Contact us anytime if you have questions or need support with your draft beer line cleaning.