If you’re in the market for a new draft system or just curious about how much they cost, you’ve come to the right place.

This blog post will discuss the factors that go into draft system prices and provide examples of what you can expect to pay to pour craft beers or other beverage products.

Keep reading to learn more!

Here is how much a draft beer system costs…

A tap system can be an essential investment for a business. While the cost varies depending on the size and features, it is crucial to understand what factors affect pricing.

Depending on the type and equipment you choose, it can range from a few thousand dollars to tens of thousands. So, what’s the cost of a draft beer system?

This blog post will take a closer look at the different types of draft systems and what factors contribute to their overall cost.

So, read for more information on draft beer systems and their cost components.

What is a draft beer system, and how does it work?

A draft beer system is a collection of devices and equipment used to serve beer, wine, or other beverages from a pressurized keg. The most important part of a draft system is the keg which is a cylindrical container that holds the product under pressure.

The basic draft beer system consists of a keg, a CO2 tank, and a coupler. Most draft systems also include a regulator, which controls the flow of CO2 into the keg, and a coupler, which connects the keg to the draft lines.

More complex draft beer systems may also include a draft tower, which allows multiple kegs to be connected, and a glycol chiller, which helps to keep the draft beer lines cold. Draft systems vary in complexity, but all share these essential components.

Draft beer systems are typically used in most bars and restaurants but can also be used in private homes.

Types of Draft Beer Systems

You’ll want to begin by determining which type of draft system fits your specific needs and budget.

The main types include:

Kegerator Systems

A kegerator is a direct-draw air-cooled tap system that works with a refrigerated unit to store and dispense beer kegs. It is a popular choice for bar owners and restaurants, as it offers a convenient way to keep kegs of beer at a consistent temperature.

Kegerators are also popular for home use, as they allow beer lovers to enjoy a fresh, draft beer in the comfort of their own homes. There are a variety of kegerators on the market, ranging from small, single-tap units to large, multi-tap units.

If you are interested in purchasing a kegerator, it is vital to consider the size of the unit, the number of taps, and the type of refrigeration.

Direct Draw Systems

Direct draw systems are beer dispensing equipment typically used in commercial settings, such as bar owners and restaurants. This comprises several components: a walk-in cooler, coupler, secondary regulators, CO2 regulator, and beer lines.

The direct draw system is designed to keep the beer cold from the time it is tapped until it is dispensed, allowing for a fresh, consistent product. This type of tap system is less complicated than a long draw or remote system, and that’s usually reflected in the total price.

In addition, this system can also help to improve the efficiency of your bar operations, in addition to lower maintenance costs. As a result, direct-draw beer systems are a popular choice for many businesses.

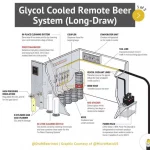

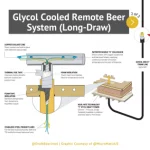

Long Draw Systems – Remote

A long-draw beer system is a beer dispensing system that uses long, uninterrupted runs of glycol-chilled beer lines to keep the beer cold from start to finish. This system is often used in commercial establishments, where a large volume of beer needs to be dispensed quickly and efficiently over a long distance.

The long draw system is increasingly popular in restaurant and bar applications, offering several advantages over traditional short draw systems. A long-draw beer and glycol system is worth considering if you’re looking for a way to dispense your beer from a remote location.

Pros and Cons of the Different Tap Systems

Kegerator Systems (Air Cooled, Direct Draw System) :

Pros

- A simple air-cooled system works by using refrigeration from the kegerator to provide cold air to chill the beer and tower.

- This system is simple and easy. The installation is a short setup time and is easy to operate.

- This system has short-line runs because the kegs are located directly below the beer tower, which means less beer waste during draft line cleaning and maintenance.

Cons

- Storage is limited, so you’ll need to store the backup kegs in a separate walk-in cooler, which is less efficient than other options available.

- You’ll need to purchase smaller kegs if you want more taps. This will require them to be changed more frequently. The downside is that smaller kegs increase your beer costs and reduce your profits.

- There are limited taps due to the reduced storage capacity inside the kegerator.

- This system takes up a lot of space behind the bar. The more faucets, the bigger the kegerator.

Direct Draw Systems (Air Cooled):

Pros

- A simple air-cooled system uses refrigeration from the walk-in cooler to provide cold air to chill the beer.

- Like its distance cousin, the kegerator, this beer tap system is simple and easy to install and operate.

- Installation costs are usually less than the cost of long-drawn remote systems.

- This system has short-line runs because the kegs are located directly behind the faucets in a walk-in cooler, which means less beer waste during draft line cleaning and maintenance. This equals higher profit margins.

Cons

- Storage is limited depending on the size of the walk-in cooler. These tap systems often share space with produce coolers. This is not recommended.

- You must install your bar directly in front of the walk-in, which limits your floor plan options for building design.

- To maintain a proper direct draw system, you can sometimes be limited in the number of taps you can install, and you don’t get all of the custom beer tower options.

Long Draw Systems:

Pros

- A long draw system gives us a much more extensive selection of options, such as cooler placement and bar placement, and doesn’t limit your floor plan design.

- Backup storage is usually not limited in space within the remote walk-in cooler. Sometimes, these tap systems share walk-in cooler space with produce coolers that aren’t recommended.

- This beer tap system gives bars and restaurants looking to have a larger selection of beers more options.

- Customers have many draft beer tower options, both basic and custom.

Cons

- Installation is usually more than the kegerator and direct draw systems cost.

- A more complicated glycol system uses chilled glycol from a glycol power pack. The glycol line runs inside a trunk line that contains the product line. The number of glycol lines will vary depending on the size of the trunkline. The more product lines in the trunkline, the more glycol lines. The glycol line makes the beer cool from the walk-in cooler to the beer tap at the tower.

- Unlike its cousins, the kegerator and direct draw, this beer tap system is complicated and can be challenging to install, manage, and operate.

- Long draws can have a long run of trunk line. This long-run of trunk line carries the beverage from Point A (walk-in cooler) to Point B (draft beer tower). The diameter of the trunk line will vary depending on the system design. This means potentially more waste during draft line cleaning and maintenance.

- This system can have more issues with foam than the other two systems.

Draft Beer System Cost by Type:

Kegerator:

The average price of a six (6) tap kegerator ranges from $1500 to $7000, depending on several factors we will share below.

The contractor should include the following in your package:

- Beer Tower and Tray

- Regulators (Secondary and Primary)

- Stainless Steel Couplers

- Kegerator

- Stainless Steel Taps

Direct Draw Systems:

The average price of an eight (8) to twelve (12) tap direct draw system ranges from $8,000 to $18,000, depending on the number of lines and several factors we will share below.

The contractor should include the following in your package:

- Beer Tower

- Drip Tray

- Regulators (Secondary and Primary)

- Stainless Steel Couplers

- Walk-in cooler or Cooler***

- Stainless Steel Taps

Long Draw Systems:

The average price of the twelve (12) to twenty (20) tap remote system ranges from $12,000 to $25,000+, depending on the number of lines and several factors shared below.

The contractor should include the following in your package:

- Beer Tower (Custom or Standard)

- Drip Tray

- Regulators (Secondary and Primary)

- Stainless Couplers

- A glycol system, also known as a glycol power pack

- Gas Blender

- Walk-in or Cooler***

- Stainless Steel Taps

Optional Add-Ons:

Foam-on-beer (FOB)

The Foam-On-Beer Detector or FOB senses when a keg is empty and shuts down the flow of beer in the line. This keeps the line full when the keg empties, so there’s no need to re-fill the line.

This reduces waste and maximizes glasses per keg, increasing profit, especially on long-line runs. A FOB can range in price from $50 – $160 per line. The price varies on manufacturer and quality. There are plastic and stainless steel options.

Glass Rinsers

A glass rinser is essential for anyone who takes their beers seriously. Quickly conditioning the glass with cold water before dispensing creates the perfect pour every time. This also removes any impurities in the glass, ensuring that your customers get the best possible product.

The art of draft dispensing is not only about the quality of the craft beer but also the presentation. A glass rinser shows that you care about every aspect of the perfect pint and will impress your customers with your attention to detail. A glass rinser can range in price from $50 – $125 per glass rinser. The price varies on manufacturer and quality.

Per Line Secondary Regulators

If you want to optimize your draft system, you need an individual secondary regulator per line. Adjust the pressure for each line individually, ensuring that your beer doesn’t foam and is dispensed perfectly every time.

Although it may cost a little more upfront, whether you have a small or large system, your beers will pour better, and there will be less waste. The secondary regulator can range from $40 to $70 per line but will vary on the manufacturer and quality.

Beer Line Maintenance (BLM)

BLM-Q is the world’s first beer line maintenance product that makes money for your restaurant. Through their 8-week cleaning cycle, you can sell the thousands of gallons of beer you would usually waste during bi-weekly cleaning cycles.

This not only saves you money, but it also helps to protect the environment by reducing the amount of beer that is needlessly dumped down the drain. This product makes sense for long-line runs and averages about $70- $90+ per line.

Nitrogen Generator

A nitrogen generator is an excellent investment for any bar or business that wants to improve the quality of its products. The higher purity of nitrogen gas produced by a high-quality nitrogen generator will improve the taste and quality of your products, making your customers happy and coming back for more.

Nitrogen generators are available at various prices and sizes, so you can find one that fits your budget and needs. Some nitrogen generator manufacturers include gas blenders in their equipment that help save money.

There are also leasing options available for businesses that want to invest in a nitrogen generator but may not have the capital to purchase one outright. Leasing options start at just $115 per month, making it easy to get started with this incredible technology.

Factors that Affect Cost:

The industry standard for the average price of a draft system per line was $1,000. This has changed so much over the last few years, especially post-pandemic. The cost of labor, materials, and manufacturers all impact the cost per line.

Here are several factors that impact draft system cost and separate contractors bidding on your business.

- Equipment manufacturer/ suppliers. There are many options out there. Many times contractors provide the least expensive options available to their clients.

- The installation. Quality companies are going to charge more, but you’re going to get a better installation. We have all seen poor draft installations.

- Quality components. Does the contractor use Brewers Association or DBI quality components? i.e., stainless steel components and barrier tubing. These components ensure quality craft beer, pour after pour.

- Design. This may be the most important factor on this list. Just because a contractor says, “we know beer,” or states that they’ve been doing installations for 30+ years doesn’t mean they know what they’re doing. Most draft systems have a ten (10) year asset life, so you’re looking at a decade-long relationship. Invest in a company to design your system that plans on partnering with you for service, maintenance, and emergencies, or stick to bottled beer and save yourself the trouble. DBI is available for a free consultation.

***This requires a walk-in or dedicated keg cooler, which would be an additional cost if there isn’t one already available. Depending on the size of the cooler, installation, permitting, etc., the price can vary between $8,000 – $20,000+.

Are You Ready To Design and Install a Draft Beer System?

Here at Draft Beer Intelligence, we always want to help you deliver the perfect pour daily. And to make sure that your draft beer systems produce GREAT-tasting beer and MAXIMIZE profits!

Contact us anytime if you need draft beer or beverage system design, installation, ongoing maintenance, or service nationwide. Together, let’s keep “DOING BEER JUSTICE!”