Draft beer system regulators help bars, restaurants, brewers, and even home bars maintain the beer’s carbonation and pour beer at the correct pressure to ensure the perfect pour for any type or style of beer.

In this article, we dive into what draft beer gas regulators are and why they are so crucial for your draft beer system.

What Is A Primary and Secondary Gas Regulator?

A draft beer system regulator is an essential piece of equipment for any draft beer system setup.

The primary regulator regulates the gas flow from the gas supply, typically CO2, Nitrogen, or beer gas tanks. This regulated gas supply can go to a gas blender or pressurize a keg directly to dispense beer (typical kegerator setup).

Meanwhile, the secondary regulator maintains consistent pressure in the line between the beer keg and the faucet. This means we retain the carbonation intended by the brewer, we have constant pour rates, and customers get the same quality pour every time they order.

Ensuring consistent quality and taste from one pour to another without a properly functioning regulator would not be easy. Additionally, having a good regulator helps keep your beer fresh and maintains its original carbonation levels over long periods.

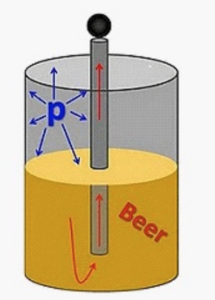

To sum up, gas is forced into the keg, and that causes pressure which pushes the beer down. That pressure then forces the beer up and out of the keg valve and through the beer line to the faucet.

This is why regulating the pressure and the type of gas is so important for the integrity of the beer. A draft beer system regulator is key to optimal flavor and pouring for draft beer system owners and consumers!

What Is A Primary and Secondary Regulator Gas Line?

There are primary and secondary gas regulators, and their usage varies on your system setup and design. The type of gas varies depending on the product you are dispensing. The beer uses CO2 or a blend of CO2 and nitrogen, while wine and cocktails use nitrogen. Primary CO2 and N2 regulators have specific connections to connect to their respective gas cylinders.

Primary Gas Line

This gas line is typically a braided tubing that can handle higher PSI pressures. The primary regulator connects to the gas cylinder and then supplies gas to either a secondary regulator or a gas blender, depending on the type of draft beer system.

Secondary Gas Line

This gas line is made of vinyl and can handle low PSI pressures. The secondary regulator is supplied gas from the primary regulator (main gas supply), then supplies gas to your keg. The vinyl gas line connects the regulator to the keg coupler. The pressure setting of the secondary gas regulator will vary based on the type of draft beer system (remote or direct-draw) and its overall design. It must be adjusted to ensure the proper gas flow to maintain carbonation and the beer flow rate. If set too high or too low, you can easily over-carbonate or under-carbonate a beer and ruin a keg.

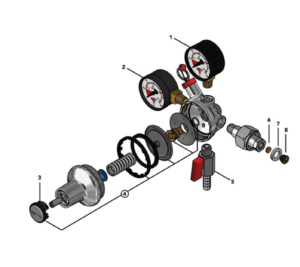

What Are The Parts Of A Gas Regulator?

- Pressure Gauge 0-60 PSI or Pressure Gauge 0-15 PSI or 0-120 lb Regulator Pressure Gauge

- 0-3000 PSI Pressure Gauge

- Tamper Evident Cap CO2

- Regulator Service Kit

- 3/8″ NPT Shut-Off or Shut-Off 1/4″ Barb

- Inlet CO2 Filter or Nitrogen Filter

- PTFE Inlet Seal or O-Ring For Nitrogen Inlet Stem

- Inlet Seal Retaining Nut or Retaining Nut – Nitrogen

How Do I Set A Draft System Gas Regulator?

Follow these steps once the regulator is securely attached to the gas cylinder:

Step 1: Close the shut-off valve on the regulator, and open the valve on the gas cylinder completely.

Step 2: Slowly turn the regulator adjustment screw until the output pressure gauge shows the desired pressure. On regulators designed for draft beer, turning clockwise will increase the output pressure, and turning counter-clockwise will decrease the output pressure.

Step 3: Open the shut-off valve on the regulator to allow gas flow from the regulator to the keg coupler. You will hear the keg pressurizing. The output needle will drop momentarily until the pressure has equalized. Then the needle will return to the point you set it at.

Step 4: The keg coupler is designed with a pressure relief valve (PRV). Pull the ring on the PRV briefly to allow gas to vent. This will permit gas to flow through the regulator and help obtain a more accurate reading on the output pressure gauge.

Step 5: Re-check the output pressure on the regulator, and if necessary, re-adjust using step #2 until the desired pressure is shown. It is always wise to follow up on any adjustment to the regulator with a brief pull of the PRV ring to ensure an accurate output reading.

Happy Pouring!

Here at Draft Beer Intelligence, we always want to help you deliver the perfect pour daily. And to make sure that your draft beer systems produce GREAT-tasting beer and MAXIMIZE profits!

Remember, proper system maintenance is crucial to ensure fresh and high-quality beer. You will surely have happy patrons or satisfied friends by monitoring the system’s temperature, pressure, and cleanliness.

Contact us anytime if you need draft beer or beverage system design, installation, ongoing maintenance, or service nationwide. Together, let’s keep “DOING BEER JUSTICE!”

Check out our other similar posts:

The Essential Components of Draft Beer Systems

How To Clean Your Draft Beer Lines and Faucets

Why Proper Draft Beer Line Cleaning Is So Important

How Clean Is Your Draft Beer System (Cleaning Recommendations Included)

The Dirty Secret You Don’t Know About Draft Beer Line Cleaning Regulations

Draft Beer Kegs Types & Sizes

Choosing Faucets For Your Draft System (Stainless vs. Brass)