Keg couplers are essential for any beer-loving household or commercial bar. They connect the keg and the tap system to allow the beer to be poured into glasses or growlers.

But what is a keg coupler exactly? What types of keg couplers are there? How do you clean and troubleshoot them?

In this blog post, we are answering your keg coupler questions and more. Here is our guide to keg couplers.

What is a Keg Coupler?

A keg coupler is essentially a device that connects the keg with your tap system. It looks like a valve, and it has three main parts:

- The body, which screws onto the top of your keg

- The probe connects directly to the keg spear to penetrate the keg to allow liquid flow.

- The handle pushes the probe into the keg spear and locks in place for product dispensing. Keg couplers are available in many different sizes and types to fit a variety of beer kegs.

Types of Keg Couplers

The most common keg couplers are the US Sankey (for American-style beers) and the European Sankey (for imported or craft beers). Other types include the AFROB, S System, Grundy, U System, G System, and more.

Each type fits different kinds of beer kegs. So make sure you get the right one for your draft system needs…

Here is a breakdown of the types of keg couplers:

- D System: Also known as a Sankey keg coupler, this standard keg coupler will work most North American beers, including craft brews.

- U System: This is the style of coupler you’ll need if you plan on tapping Guinness, Harp, Kilkenny, and other select beers from the UK.

- S System: Similar to the D System coupler, an S System coupler is also known as a European Sankey coupler. It works with popular European imports, including Heineken, Becks, and Amstel.

- A System: Designed for use with German beers, including Warsteiner, Paulaner, and Spaten, an A System coupler slides over the top of the keg stem. It is also referred to as a German Slider coupler.

- G System: For use with popular UK beer brands, such as Bass and Boddington’s, the valve stems on a G System keg are shaped like a circle with three flat sides.

- M System: Similar to the A System coupler, an M System locks into place by sliding over the top of the keg. It is compatible with several German beers, including Schneider, Aventinus, Einbecker, and Veltins.

- KeyKeg: The KeyKeg or K System is a new setup for keg tapping that uses single-use plastic kegs. KeyKeg systems are gaining in popularity with select European breweries and US winemakers.

Check out our Keg Valve List if you’re not sure which style of coupler you need for a specific brand of beer.

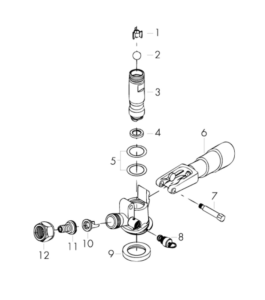

Parts of a Keg Coupler

Keg couplers have several parts that work together to ensure your tap system can draw beer from your keg. The handle engages the probe to the keg to ensure beer can flow from the keg to your beer faucet, the body connects the coupler to the keg, and the probe and its seal prevent beer from leaking out.

Additionally, many keg couplers have a pressure relief valve to prevent over-pressurization of your tap system. Some of the parts inside the coupler may vary depending on the manufacturer.

Here’s a breakdown of the parts of a D-System keg coupler:

- Check Ball Retainer

- Check Ball, Keg Couplers

- Probe

- Probe Seal, Keg Couplers

- O-Ring – Body, Keg Couplers

- Handle Assembly

- Hinge Pin, Couplers

- Pressure Relief, Couplers

- Sankey Tap Bottom Seal

- Check Valve, Keg Couplers

- Gas Hose Nipple, 7480 Couplers

- Hex Nut

How to Clean a Keg Coupler

Cleaning your keg coupler ensures that your beer stays fresh and delicious. Here are the steps we recommend at least every two to three weeks or every time you tap a new keg:

Step 1: Start by disconnecting the body from the keg and removing the handle.

Step 2: Then, use warm water and soap or sanitizer to clean all parts of the keg coupler. Make sure you get into all nooks and crannies!

Step 3: Once done, rinse with cold water and let the keg coupler air dry.

Step 4: Reconnect the body to the keg, and you’re ready to pour!

Keg Coupler Troubleshooting

If your beer isn’t pouring correctly, there may be something wrong with your keg coupler. Before doing any troubleshooting, make sure that all of the parts are securely connected and check that the seal is in place.

Also, make sure you are using the correct type of coupler. If you have to force the coupler to attach to the keg, it may not be the right type. Be sure to match your beer with our Keg Valve List.

If everything looks ok and you have the correct coupler, try adjusting the handle position to see if that helps. If not, it may be time to replace your keg coupler.

In conclusion, a keg coupler is essential to any tap system used for dispensing beer. Many types of keg couplers are available, so make sure you get the right one for your needs.

Proper maintenance and cleaning are also necessary to keep your beer tasting great. If you encounter problems pouring beer from your tap system, check the keg coupler before placing a service call.

Here at Draft Beer Intelligence, we always want to help you deliver the perfect pour daily. And to make sure that your draft beer systems produce GREAT-tasting beer and MAXIMIZE profits!

Remember, proper system maintenance is crucial to ensure fresh and high-quality beer. You will surely have happy patrons or satisfied friends by monitoring the system’s temperature, pressure, and cleanliness.

Contact us anytime if you need draft beer or beverage system design, installation, ongoing maintenance, or service nationwide. Together, let’s keep “DOING BEER JUSTICE!”