A draft beer system that produces high-quality beer and maximizes profit starts with the design.

The beer faucet used to dispense beer is crucial to the end product. Unfortunately, the value of the faucet and the type of alloy used is often an afterthought.

So, where do faucets fall on your list of essential features in your draft beer system design?

The quality of the product poured from those faucets is what brings your customers back. As a result, the beer faucet you choose and its quality should be well-thought-out.

When considering the essential factors in choosing an alloy, resistance to corrosion, metallic leaching, and the beverage’s taste are at the top of the list.

Here is what you need to know when choosing faucets for your draft beer system…

What types of draft beer faucets are there?

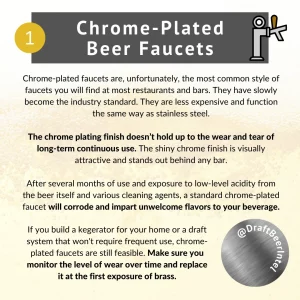

Chrome-Plated Beer Faucets:

Chrome-plated faucets are, unfortunately, the most common style of faucets you will find at most restaurants and bars. They have slowly become the industry standard. They are less expensive and function the same way as stainless steel. The chrome plating finish doesn’t hold up to the wear and tear of long-term continuous use. The shiny chrome finish is visually attractive and stands out behind any bar.

After several months of use and exposure to low-level acidity from the beer itself and various cleaning agents, a standard chrome-plated faucet will corrode and impart unwelcome flavors to your beverage.

If you build a kegerator for your home or a draft system that won’t require frequent use, chrome-plated faucets are still feasible. Make sure you monitor the level of wear over time and replace it at the first exposure of brass.

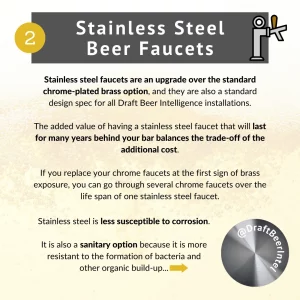

Stainless Steel Beer Faucets:

Stainless steel faucets are an upgrade over the standard chrome-plated brass option, and they are also a standard design spec for all Draft Beer Intelligence installations.

The added value of having a stainless steel faucet that will last for many years behind your bar balances the trade-off of the additional cost. If you replace your chrome faucets at the first sign of brass exposure, you can go through several chrome faucets over the life span of one stainless steel faucet.

Stainless steel is less susceptible to corrosion. It is also a sanitary option because it is more resistant to the formation of bacteria and other organic build-up.

For that reason, stainless steel should be a must if you want to dispense cocktails on tap, wine on tap, coffee on tap, or kombucha on tap. The acidity in these beverages will almost immediately corrode the finish of a plated-brass faucet and cause whatever winds up in your glass to become undrinkable.

At DBI, we understand that the industry is constantly changing; one-week draft cocktails are hot, and then the next week, wine on tap sounds good. We design and build our systems to accommodate these changes without additional costs from our customers, and this is another reason we lean on stainless steel faucets and fittings.

Polished Brass Beer Faucets:

There are options if you want the look of polished PVD brass for your faucets. A polished brass draft beer faucet delivers the same affordability and functionality as the standard chrome-plated faucet.

There is an option to purchase a stainless steel faucet with a tarnish-free brass PVD finish. This type of faucet has brass on the outside but with the durability of stainless steel on the inside.

Which type of faucets does DBI recommend?

We always recommend stainless steel; it is one of our many draft beer system design standards.

Some components of your draft beer system will cost more upfront, but they will deliver long-term quality pour after pour. Stainless steel will last decades if adequately maintained, and it’s what we use on every Draft Beer Intelligence installation.

Chrome-plated faucets will last only 6-12 months before they start wearing away and the brass is exposed. The difference in cost is usually less than $5 per standard beer faucet to upgrade to stainless steel.

Why we recommend stainless steel beer faucets:

There was a case study done in 2000 by Lorraine D. Doucet and Forrest Thornton of Beertown, where they wanted to confirm the following:

1) Does a traditional chrome-plated dispensing system contain more bacteria and yeast than a non-traditional stainless steel system? (*one must ask, how, why, and when did a chrome-plated system become the industry standard and, more specifically, the traditional type of dispense system?)

2) Learn how much copper and lead leached from the exposed brass surface areas.

3) Compare the taste profiles of Budweiser and Bud Light samples drawn from chrome-plated brass and stainless steel faucets.

Let’s look at what was discovered…

Bacteria and Yeast in Stainless Steel Vs. Chrome-Plated Faucet

They discovered 28% fewer total heterotrophic bacteria, 53% fewer coliform bacteria, and 49% fewer yeast cells in the stainless steel faucets when pouring Budweiser.

Bud Light samples drawn from the stainless steel faucets demonstrated an even more significant reduction in microorganisms. Overall, the samples average 36% fewer total heterotrophic bacteria, 65% fewer coliform bacteria, and 74% fewer yeast cells than the total percentage of microorganisms found in samples from chrome-plated faucets.

All beer samples during this study came from the same kegs and lines. The difference in bacteria and yeast percentages is due solely to the faucets.

Copper and Lead in Stainless Steel Vs. Chrome-Plated Faucet

When testing the copper levels in beer samples, it found higher levels of copper in the chrome-plated faucets. On the other hand, the stainless steel faucets proved decisive by not increasing copper levels.

It confirmed that the copper levels in beer samples drawn from stainless steel faucets were directly attributed to the chrome-plated faucets. The chrome-plated faucets leached significantly higher levels of copper than the stainless steel faucets.

No lead was detected in the control samples from the traditional chrome-plated faucets. But, trace amounts were detected in the stainless steel faucets.

Comparison of Taste

Both faucets types were set up at a Nashua, N.H. pub for taste tests during this study. The tests were conducted using Budweiser from the faucet and the bottle.

A total of 18 samples were taken at 42F. The tests found that the bottled Budweiser and the Budweiser drawn from the stainless steel dispensing system contained 0.006 mg/l copper and no lead.

This amount of copper is the base level contained in bottled Budweiser.Subsequently, there was no additional metallic flavor added to the beer samples from the faucet than the flavors in the bottled beer.

Conclusion

If you aim to offer a similar taste of draft beer to its bottled counterpart, the draft beer system design is critical to achieving this successfully.

You will need to partner with a draft beer system design and installation company that specs materials that don’t disrupt taste or add to the metallic undertones of a beer poured from copper-heavy faucets. Higher quality materials are the only way to maintain the flavor the brewer intended for every pour.

In this study, the only case a taste tester found the beer to taste precisely like its bottled counterpart was when poured from an all stainless steel faucet. However, it is essential to note that these faucets were cleaned and well-maintained before the tasting. It is equally vital to keep faucets clean consistently.

Selecting a stainless steel faucet provides your customers with a clean, crisp, fresh taste like the bottled beer equivalent. You can read the full study and download the PDF here.

Cheers to you for learning more about which beer faucet is best for you!

Here at Draft Beer Intelligence, we always want to help you deliver the perfect pour day after day. And to make sure that your draft beer systems produce GREAT tasting beer and MAXIMIZE profits!

Contact us here anytime if you need draft beer system design, installation, ongoing maintenance, or service nationwide. Together, let’s keep “DOING BEER JUSTICE!”