Glycol power packs are essential to any long draw or remote draft beer system. Any commercial draft beer system that dispenses beer long distances can benefit from a glycol cooling solution.

Glycol power packs use a mixture of food-grade antifreeze and water to consistently and uniformly chill your commercial draft beer system. This glycol mixture is circulated through the lines of your draft beer system, maintaining a consistent and uniform temperature so that every pint you pour is perfectly chilled.

Glycol power packs are available in a variety of sizes and configurations to meet the specific needs of your glycol draft beer system. With a glycol beer chiller, your beer can travel up to 600 feet and maintain a consistent, perfectly chilled temperature, so you can be confident that every pint you pour is perfect. This makes them an ideal solution for large-scale commercial operations. In addition, glycol beer chillers are highly efficient and require minimal maintenance, ensuring that your draft beer system will always be up and running when needed.

For the remainder of this article, we will discuss glycol cooling systems and the glycol chiller power packs that keep the beer lines ice cold, pour after pour.

What is a glycol power pack?

The glycol power pack is an essential component of a draft beer system. It is a refrigeration unit that chills a propylene glycol and water mixture contained in a reservoir between 29˚ to 32˚ F. This is called a swing or differential. The glycol power pack turns off when the temperature reaches 29˚ and turns back on at 32˚ F. The bath mixture should result in an approximate 2- 5˚ F freezing point or 33 – 35% glycol viscosity mixture. The freezing point is adjusted by the amount of glycol in proportion to the amount of water.

The glycol power pack constantly pumps and circulates the antifreeze mixture through the beer system. This chilling process prevents beverages from getting warmer as they travel from the keg to the tap, ensuring that customers always enjoy a cold, refreshing pint. It is crucial to ensure that it is properly maintained. Regular cleaning and maintenance will help to extend the life of the glycol power pack and ensure that it continues to perform its functions properly.

What does a Glycol Chiller do for a Draft Beer System?

Most bars and restaurants have a draft beer system. The most common are kegerator, direct draw, and long draw systems. These systems have pros and cons in delivering beer from the keg to the beer tower.

All three systems have their way of maintaining perfectly chilled temperatures for the beer lines.

- Kegerator = Air-Cooled

- Direct Draw = Air-Cooled

- Long Draw = Glycol Power Pack aka Glycol Chiller

The glycol chiller allows us to maintain proper beer temperature over long distances. This system gives us flexibility in how we layout our bars and restaurants.

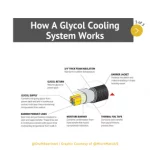

How do glycol cooling systems work?

Glycol cooling systems have become very popular because of their ability to maintain perfectly chilled temperature beer at long distances.

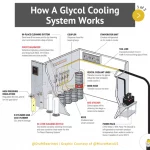

A glycol system consists of the following:

- Glycol Chiller Power Pack – refrigerated glycol unit

- Trunk House, Trunk Line, or Python – contains barrier tubing beer lines taped directly to the glycol lines and covered with 3/4″ wall insulation (minimum).

- Glycol Cooled Beer Tower – Glycol lines are set up to come in contact with each beer shank.

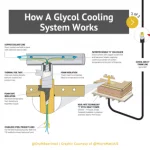

In a long-draw draft beer system with a glycol chiller, the beer in the keg is cooled by the walk-in cooler, and the beer in the beer lines, dispensing tower, and beer faucets are kept cold by the continual flow of glycol through the glycol lines located in the trunk line. You can have multiple supply and return glycol lines in trunk line bundles.

Two types of heat exchangers are used in modern glycol chiller power packs. Those heat exchangers are cold plates and cooling coils.

The glycol chiller and this cooling method allow beer towers to be located remotely from the walk-in cooler while maintaining the perfect temperature for the beer.

What are the parts of a glycol chiller power pack?

A few different parts and systems make up a glycol chiller. These systems work in tandem to chill, circulate and maintain the temperature of the glycol and the beer.

The parts that make up a glycol chiller are:

Refrigeration condensing unit

The refrigeration condensing unit works with the heat exchanger to cool the power pack’s glycol bath.

Digital thermostat

The digital thermostat controls the set points of the glycol chillers bath.

Bath-level sight glass

Some of the glycol chillers on the market have a bath-level sight glass that lets you know the propylene glycol level. If the glycol levels are low, it can cause your chiller to fail.

Seal insulated bath

The bath stores the propylene glycol and the heat exchangers.

Glycol pump and motor

The glycol pump and motor pump propylene glycol from the walk-in cooler to the draft beer tower.

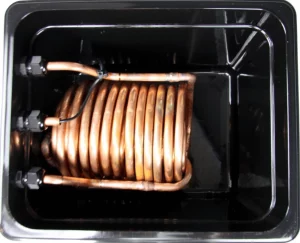

Heat exchanger

The heat exchanger has refrigerant and cools the glycol. There are two heat exchangers used in glycol chillers, and they both have pros and cons.

- Cold Plate – The cold plate is immersed in the glycol bath. The refrigerant and glycol flow through alternating channels, resulting in excellent heat transfer. The returning glycol travels through the cold plate of multiple panels brazed together.

- Cooling Coil – This setup submerges a refrigerated copper coil that is wrapped around the interior of a large insulated bath. The glycol is then chilled by coming in contact with the refrigerated copper coil.

Manufacturers will design and build their glycol chiller power packs with both heat exchangers.

The cold plate is the modern heat exchanger and is much more efficient at cooling but is also more prone to damage if the bath is not maintained and foreign particles are pumped through it. They will also become damaged if the glycol viscosity is too low and internally freezes. Due to its efficiency in cooling the glycol, the cold plate usually has a smaller bath.

The cooling coil is an older technology and has been around for a long time. This setup is not as efficient and requires a much larger glycol bath than glycol chillers with cold plates. This chiller is less prone to heat exchanger damage from foreign particles and damage from freezing.

How do I select a glycol chiller power pack?

Glycol chiller power packs at a fundamental level are selected by the length of the distance from the walk-in cooler to the point of dispense, plus the number of beer faucets.

Ambient temperatures also play a large part in designing and engineering these systems. Suppose the glycol chiller power packs are placed in a location with no air circulation or where it’s hot, such as a rooftop. In that case, most glycol chillers will struggle to maintain temperature and have a shorter life expectancy, causing more service calls in the future.

We always suggest reaching out to a draft beer system installation company for support in selecting the correct glycol power pack for your application.

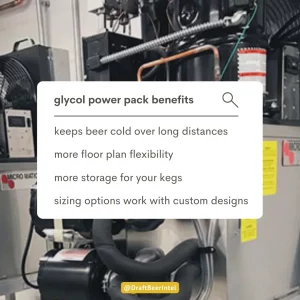

What are the benefits of using a glycol power pack in a draft beer system?

There are a lot of benefits to using a glycol power pack for your next draft system.

- It allows flexibility in developing a floor plan for your bar or restaurant because you can separate the walk-in cooler and beer taps.

- It maintains perfectly chilled temperature beer over long distances.

- You’ll have more storage for your kegs vs. kegerator-style setup.

- You can get creative with your draft beer towers and do custom designs while dispensing cold beer. Glycol chiller power packs come in all sizes, so small bars can also use them if they want to get creative with their beer tower.

Where can you buy a glycol power pack?

Glycol chiller power packs can be found online through several retailers. These suppliers carry different manufacturers, types, and sizes of glycol power packs.

Please keep in mind when making a purchase not all glycol power packs are built the same and don’t have the same warranty.

We recommend making your purchase through your preferred draft beer system installer. This ensures you receive not only the best price but also installation.

What is the price for a glycol power pack?

For this section, we will generalize the price of a glycol power pack without getting into the specific manufacturers.

The price of a glycol power pack will vary on the manufacturer, the quality of its components, its size (horsepower), the number of pumps, and its warranty.

The range from 1/6 HP – 1.5 HP can be $1200 – $9200, not including installation and other miscellaneous items needed to operate a glycol cooling system properly.

What is Glycol Chiller Power Pack Preventive Maintenance?

By now, you know that glycol chillers are critical components of long-draw dispense systems. Chilled glycol helps maintain the draught beer temperature in the beer lines between the keg and the faucet.

Glycol chillers are much less expensive to maintain than replace; regular maintenance will increase their service life and dependability. A qualified technician should service the glycol chiller twice a year. Draft Beer Intelligence recommends quarterly service, especially if used extensively.

Here are some recommended quarterly maintenance practices. Some of these practices are quick visual checks that should be completed daily by your bar or operations team; be sure to check with your manufacturer for items and procedures specific to your glycol power pack and glycol chiller.

Following these simple practices ensures that your glycol chiller will provide years of trouble-free service:

- Glycol strength – Check glycol viscosity with a refractometer and its condition. Make sure there are no foreign particles inside the glycol bath. Make sure the glycol viscosity follows the manufacturer’s recommendations. Typical ranges are 30-35% glycol.

- Visually inspect trunk lines and check for signs of ice build-up, insulation damage, and glycol leakage.

- Inspect the refrigeration condenser for dirt and airflow obstructions. Remove and clean all debris from the condenser coil.

- Check glycol pumps. Make sure the pump sounds smooth. Check all connections and insulation for signs of leaks or missing insulation.

- Check the glycol pump motor. Ensure the motor is not running hot, has minimal vibration, and sounds smooth.

- Glycol Bath Temperature – Ensure the bath temperature is within the range specified by the manufacturer or your draft beer system installation company.

- Glycol Bath – Keep the bath covered to prevent foreign objects or debris from entering the bath. This can damage the pumps and heat exchanger. You also want to keep the cover closed to prevent water vapor from diluting the strength of the glycol.

Are You Ready To Install a Glycol Power Pack?

Here at Draft Beer Intelligence, we always want to help you deliver the perfect pour daily. And to make sure that your draft beer systems produce GREAT-tasting beer and MAXIMIZE profits!

Contact us anytime if you need draft beer or beverage system design, installation, ongoing maintenance, or service nationwide. Together, let’s keep “DOING BEER JUSTICE!”