Nitrogen gas generators are an increasingly popular option for businesses in various industries. There are many reasons to use nitrogen, including preventing spoilage, preserving medications, and protecting against corrosion.

Nitrogen generators are an essential part of many different industries, and they’re only becoming more popular as time goes on.

If you’re interested in learning more about nitrogen generators or if you think one might be right for your business, we want to support you.

This article explains what a nitrogen generator is and how it can benefit your draft system…

What is the difference between a PSA Nitrogen Generator and Membrane Nitrogen Generator?

There are two main types of nitrogen gas generators used for nitrogen generation. A pressure swing adsorption nitrogen generator is also known as a psa nitrogen generator and a membrane nitrogen generator.

Membrane nitrogen generators typically produce nitrogen gas at purities up to 99.5%, while psa nitrogen generators can achieve purities up to 99.9995%.

Psa nitrogen generators can supply high-purity nitrogen gas but are not practical for a restaurant or bar application. We use membrane nitrogen generator systems in the food and beverage industry to produce our nitrogen gas.

The remainder of this article will focus on these types of nitrogen generators.

What Does A Nitrogen Generator Do?

A nitrogen generator is a machine that takes air from an air compressor into a filter membrane and outputs nitrogen, usually into a storage tank for future use. The process is known as selective separation and benefits all sorts of applications.

Nitrogen generators are used in various industries, including food and beverage, pharmaceuticals, chemicals, electronics, oil and gas, metal processing, and more. In each case, nitrogen gas (n2 gas) is used for different purposes.

For example, nitrogen gas is used in the food and beverage industry to keep foods fresh and free from spoilage. In the pharmaceutical industry, nitrogen gas is used to keep medications sterile. And in the oil and gas industry, nitrogen gas is used to prevent corrosion in pipelines.

In this article, we will specifically talk about nitrogen generators for your draft beverage systems.

How Does A Nitrogen Generator Work?

The nitrogen generation separation process is pretty simple. A nitrogen generator is a device that takes in atmospheric air and outputs nitrogen gas. The air around us comprises about 78% nitrogen and 21% oxygen.

A nitrogen generator first uses an air compressor to supply compressed air to a filter membrane that can separate nitrogen molecules from the air. As the compressed air moves through the membrane, the nitrogen molecules are separated from other molecules.

The quality of the membrane determines the purity of the nitrogen produced. Nitrogen purity is essential because the nitrogen gas comes in contact with the beverage product you are dispensing from your draft system. This separation process leaves only nitrogen gas behind.

The nitrogen gas is stored in tanks until it’s needed. When it’s time to use the nitrogen, the gas is sent through a gas blender, and then secondary regulators supply a blend of nitrogen gas and CO2 to your draft system kegs.

The Benefits of Using a Nitrogen Gas Generator(s) To Serve Draft Beer

If you’ve ever been to a bar or restaurant serving draft beer, those taps are likely connected to a nitrogen generation system in the back of the restaurant. That nitrogen generation system is a large part of beverage dispensing for a draft system.

Nitrogen generators are becoming increasingly popular in the food and beverage industry because of their many benefits and low cost. Here are just a few of the benefits of using a nitrogen generator to serve draft beer:

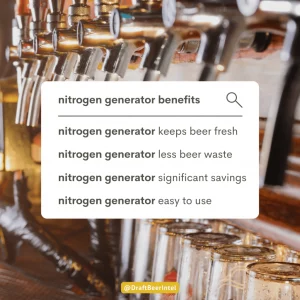

-Nitrogen gas generators help to keep your beer fresh for longer.

This is because nitrogen gas is an inert gas less reactive than oxygen, which slows down the oxidation process. This means your beer will stay fresher, tastier, and more carbonated for longer.

Nitrogen gas purity is also essential. Many nitrogen generator suppliers have low-quality filter membranes that don’t provide high-purity nitrogen gas. The lack of purity can result in more oxygen or other contaminants entering your beer, leading to oxidation of the beverage product.

-Nitrogen gas generators can offer significant savings.

If you’re buying nitrogen gas cylinders from a gas distributor, they typically have several options. You can order 100% pure nitrogen cylinders or a 75/25% blend, also known as Guinness or beverage gas. Nitrogen cylinders are an expensive option; they take up a lot of floor space and make managing the draft beverage system operation much harder.

There is very little energy consumption in running your nitrogen gas generator, and most of them operate off a standard 120V – 20 amp outlet. However, a reliable nitrogen generator system has low operating costs and can offer higher purity than its nitrogen cylinder cousins. Having an onsite nitrogen generator system allows you to produce your nitrogen gas. It will enable you to bypass the gas distributors, which is an overall cost savings to your operation and minimizes draft beverage system downtime.

…and it’s always a Friday when your draft system goes down, and you realize the gas distributor missed their delivery, so now you can’t pour beer which equals a loss of sales.

-Nitrogen generators are easy to use.

You must connect the nitrogen gas generator to your draft beer system. Our preferred nitrogen generator has a built-in gas blender that makes the installation process much more manageable. This setup allows us to run the proper gas blends into your draft beer system.

Depending on your nitrogen generator supplier, multiple sizes are usually available based on the level of nitrogen production needed for your application. More extensive operations with more taps will require more nitrogen gas production, so the nitrogen generator will need to be sized to provide a continuous supply of nitrogen gas.

The maintenance is simple and typically requires the filter membrane to be replaced twice yearly.

A nitrogen generator is an excellent option if you’re looking for a way to keep your beer fresher for longer and save money.

What Is Nitrogen Blending

Almost every carbonated, draft-dispensed beverage can benefit from CO2 and Nitrogen blending. Without the mixing, your draft beer system can be inconsistent – very heavy foam on some pours and very flat pours on others.

By blending CO2 with nitrogen separated from the surrounding environment, you can reduce beverage waste and protect quality. We partner with Green Air Supply as our preferred nitrogen gas generator supplier. The purity level of their system is fantastic, and more than anything, it’s reliable.

What Is the Cost of a Nitrogen Generator?

Nitrogen generators are generally available from around $6000 to about $16000. The nitrogen generator’s cost will vary depending on your nitrogen gas production requirements and the nitrogen purity. A high-purity nitrogen generator will cost more than some of the low-budget systems on the market. The higher purity of the nitrogen gas produced will benefit the quality and taste of the beverage product you are dispensing to your customers.

When working with a contractor to purchase a nitrogen generator, you want to ensure they properly size it to process and generate nitrogen gas at a flow rate that will supply enough n2 gas to your draft system.

There are also leasing options available for those companies that want to invest in a nitrogen generator system but may not have the capital to purchase one. The leasing options will also vary between $115 – $185 per month depending on the nitrogen gas generator supplier and the nitrogen production needed for their application.

Two of the main benefits of leasing:

- Repairs should be part of your monthly fee.

- Preventive maintenance, which includes replacements of the filter membrane.

Nitrogen generators are reliable, but failures can happen. Maintenance is also a plus to draft system operation because technicians can catch system issues before failure occurs.

Are You Ready To Make Some Upgrades To Your Beverage System(s)?

Here at Draft Beer Intelligence, we always want to help you deliver the perfect pour daily. And to make sure that your draft beer systems produce GREAT-tasting beer and MAXIMIZE profits!

Contact us anytime if you need draft beer or beverage system design, installation, ongoing maintenance, or service nationwide. Together, let’s keep “DOING BEER JUSTICE!”

Check out our other similar posts:

How To Clean Your Draft Beer Lines and Faucets

The 3 Types Of Draft Beer Systems + How They Work

Why Proper Draft Beer Line Cleaning Is So Important