Are you looking for an easy and affordable way to ensure you’re serving the best beer, reducing beer waste, and NOT pouring profits down the drain?

You can achieve ALL this by installing draft beer Foam On Beer (FOB) detectors in your draft beer system!

In this blog post, we answer all your FOB questions and more. Here is our guide to Foam On Beer Detectors (FOBs).

What is a FOB, and Why Are They Important?

A draft beer FOB, also known as a “foam on beer detector,” is essential in the draft beer industry, especially for long draw or remote draft beer systems. It is used to keep beer in the lines when a keg empties. Without a FOB, a beer line would empty when a keg runs out of beer. Filling this line back up with beer will cause foam to be dispensed at the beer faucet. Depending on the length of your lines, you can waste a pitcher to several pitchers of beer pouring foam down the drain and waiting for the beer to flow again. All of this waste is lost profits.

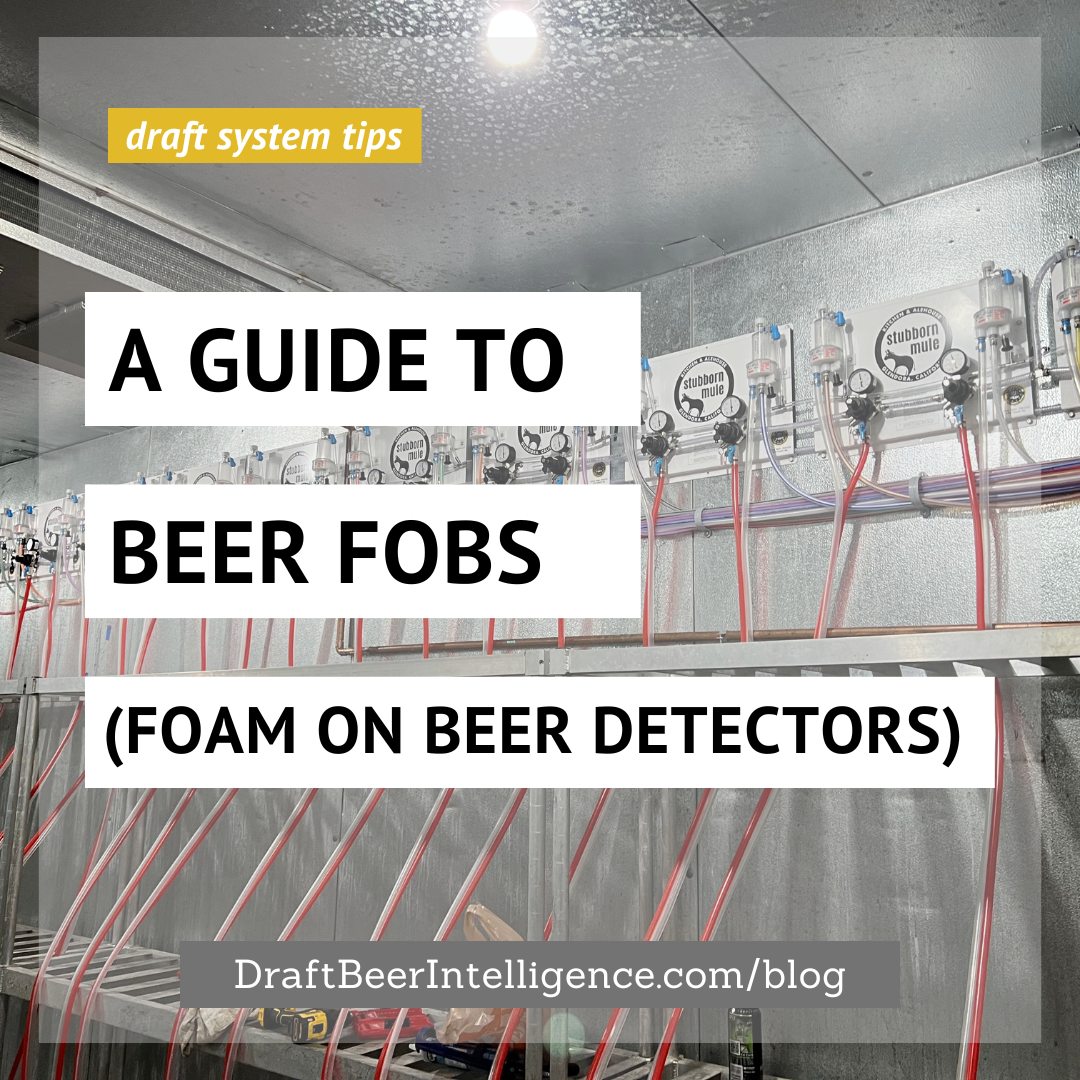

FOBs are installed in your keg room and generally on a panel with secondary regulators, wall brackets, and other draft beer system components. Several styles of FOBs are available on the market, and they all vary in cost and operation. The higher-end FOBs are usually made with stainless steel, while the more economical FOBs are made of plastic.

What Are The Benefits Of Using FOBs?

Reduce Beer Waste

When a FOB is installed on a long draw beer line and the keg empties, the beer flow is stopped immediately. The beer line remains full of beer instead of filling with foam.

Keeping the lines full of beer eliminates the need to refill the beer lines and purge the system with beer when tapping the next keg. This will significantly reduce beer waste. The actual reduction is based on the length of the draw of the beer system being considered.

Increase Profits

Studies have shown that FOBs can increase profits from draft beer sales when installed on a long-draw beer dispensing system and even reduce pour cost per keg change! Imagine how quickly that could add up for your draft beer system.

With so many advantages, it’s easy to see why investing in FOBs is worth considering when setting up a draft beer system.

How Do FOBs Work?

The FOB operates from the beer flow, which means that beer flowing from the keg forces the float inside the FOB into the up position, allowing beer to flow to the faucet.

When a keg empties, the float drops down, stopping the beer flow from the keg. Tap a new keg and reset your FOB. Pushing the vent mechanism releases the gas/foam from the chamber. This function allows the beer to flow from the keg into the chamber, lifting the float and allowing beer to flow to the faucet.

What Are The Parts of FOBs?

How Do You Clean FOBs?

FOBs must also be maintained and cleaned regularly, the same way beer lines are cleaned. As we mentioned earlier, several types of FOBs are available on the market, so always refer to the manufacturer’s directions for cleaning your specific FOB.

You can clean your FOBs by following these steps:

- Push & Hold Connector.

- Pull Out Vent

- Push and Hold Connector

- Pull out Lifter

- Loosen & Unscrew Top from Sight Glass

- Loosen & Unscrew Sight Glass from the Base

- Remove Float

Clean & brush all parts with appropriate tools. Only use recommended cleaning chemicals.

It is crucial that when cleaning your draft beer system and lines, you include the cleaning of your FOBs; otherwise, the flavor of your beer will be affected.

Happy Profitable Pouring!

Here at Draft Beer Intelligence, we always want to help you deliver the perfect pour daily. And to make sure that your draft beer systems produce GREAT-tasting beer and MAXIMIZE profits!

Remember, proper system maintenance is crucial to ensure fresh and high-quality beer. You will surely have happy patrons or satisfied friends by monitoring the system’s temperature, pressure, and cleanliness.

Contact us anytime if you need draft beer or beverage system design, installation, ongoing maintenance, or service nationwide. Together, let’s keep “DOING BEER JUSTICE!”