When you consider installing a draft beer system in your restaurant, bar, pub, or brewery (or re-designing your existing system), it’s essential to know what the different types are so you can decide on the best fit for you and your beer.

During the selection process, keep in mind that the primary function of any draft beer system is to move the beer from the keg to the faucet in the shortest amount of time without damaging the product.

There are three draft systems options for dispensing beer: remote glycol cooled, air-cooled, and direct draw.

All of these share the same goal of dispensing the beer to deliver a perfect pour, pint after pint. To attain this goal, we need all three options to be correctly balanced, temperature-controlled beer from the kegs to the taps, but the design of each system type will vary in process, cost, and the components involved.

Here are the three types of draft beer systems, their main components, and how they work:

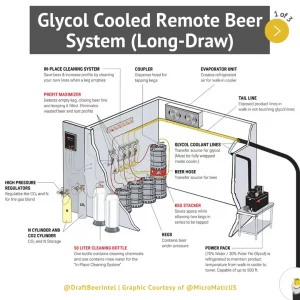

Type 1: The Glycol Cooled Remote Beer System (Long-Draw)

This is one of the most popular draft beer systems and is an excellent choice for any long-draw dispensing setup (typically, running 25 ft or longer) due to its ability to maintain the cooler temperature and deliver cold beer at long distances.

In a glycol-cooled remote beer system, the beer in the keg is kept cold by the cold air in the walk-in cooler. The beer in the beer lines, beer tower, and faucets are kept cold by the continual flow of glycol through the coolant lines designed to take the cold temperature of draft beer from the walk-in cooler and transport it to the dispensing tower at a consistent temperature.

The glycol-cooled remote beer system is the more expensive of the three (3) draft systems.

The Main Components Of A Glycol Cooled Beer System

- GLYCOL POWER PACK

- Compressor

- Evaporator fan

- Thermostat (to regulate the temperature)

- Glycol reservoir with a coil or plate chiller (contains cooling refrigerant)

- Supply and return lines

- Glycol trunk lines

- TRUNKLINE

- Beer lines

- BEER TOWER

- Faucet(s)

- Drip tray

How It Works

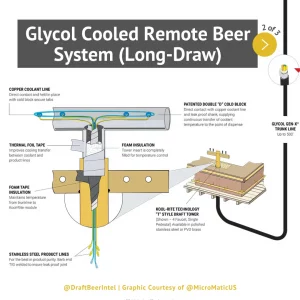

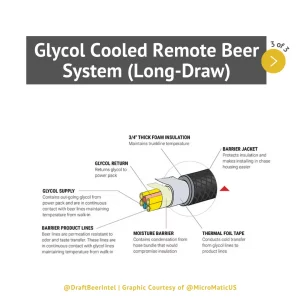

The trunk housing carries the beer and the glycol cooling lines that keep the beer cold in a glycol system.

The lines are built in a factory where the beer and coolant lines are wrapped together, using a vapor barrier, foil tape, insulation, and some manufacturers provide a barrier jacket. This insulated trunk line consists of multiple beer lines tightly taped to the coolant lines, so all the beer lines are in direct contact with the coolant lines the entire length of the trunk housing. Trunk lines runs have been known to go up to 1,000 ft.

The sole purpose of the glycol power pack is to refrigerate and circulate the glycol coolant from the walk-in cooler to the faucet shank and back to the power pack for re-cooling.

The coolant temperature is cycled between 28F – 34F by an adjustable thermostat. The power pack pump pushes the cold glycol out of the power pack into the supply glycol line, through the trunk line, up through the tower behind the faucets, and returns to the glycol power pack through the return glycol line.

Then the returning glycol is re-cooled and continually pumped back through the system keeping the beer at its proper serving temperature.

How Effective is a Glycol Cooled Beer System?

This system is the most complex and the most expensive of all three draft systems. This system has many benefits, but it has its opportunities as well.

The long draw system opens up so many design and layout options due to the flexibility of the equipment placement. You can place your beer (walk-in cooler) far from the beer tower, but over these long distances, it opens up opportunities for dispense problems, increased equipment costs, cooling issues, and beer waste.

With this said, a properly designed and installed long-draw system can offer a decade of cold beer, perfect pours, and profits.

Key Tips:

- Select your glycol power pack by the length of the distance from the walk-in cooler to the point of dispense.

- Do not mount the glycol power pack above the cooler or in an area with minimal air circulation. Most glycol power packs need to operate in a space with an ambient temperature of 50-90F.

- Confirm you have the proper glycol mix ratio (refer to the manufacturer requirements)

- Maintain a walk-in temperature of 34-38F

- Request full barrier trunk line tubing from your installation vendor

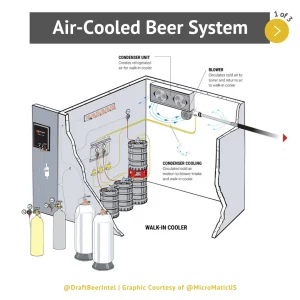

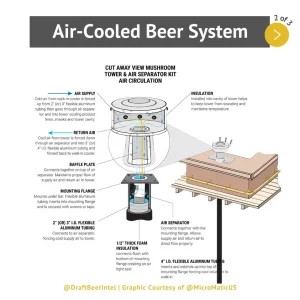

Type 2: The Air Cooled Beer System

Air-cooled systems are any system that uses circulating cold air to keep the beer cool in the walk-in cooler, around the beer lines, and up to the faucet – that’s about as simple as it gets. The method of forcing chilled air from the walk-in cooler to tap was the only way to chill your draft lines until the arrival of glycol. Despite its status as the O.G. when it comes to cooling, it is still a viable and less expensive option to glycol chilling for short-draw draft systems.

The cost of an air-cooled beer system is relatively low, making them a great starting point for most beer enthusiasts or mom-and-pop restaurant owners.

The Main Components For An Air-Cooled Beer System

- FORCED AIR BLOWER

- PVC Blower tubing + insulation

- Air Duct

- TRUNKLINE

- Beer lines

- BEER TOWER

- Beer Faucet(s)

- Drip tray

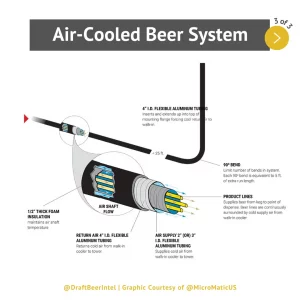

How It Works

A forced air-cooled system is any system where beer is stored, chilled, and tapped in a walk-in cooler. The beer is transferred to the beer faucet through trunk lines at a remote location from the walk-in cooler. The beer in the keg, beer line, and beer tower attached to the faucet is cooled by circulated air.

This type of system has two methods of execution, a dual duct or a single duct system.

Single Duct System:

The trunk line(s) are housed inside a smaller diameter (i.e., 3″) flexible tubing, which is contained with a larger diameter (i.e., 4″) insulated flexible metal tubing that is connected to the cooler at one end and the beer tower. A blower fan is mounted in the walk-in cooler forces cold air through the smaller diameter tubing to the beer tower behind the faucet(s) to keep the beer lines cold. Once the cold air has reached the beer tower, it returns to the cooler through the larger diameter tubing.

Dual Duct System:

The trunk line(s) are housed inside a larger diameter flexible tubing connected to the cooler and the beer tower at the other end. A blower fan mounted in the walk-in cooler forces cold air through the tube to the beer behind the faucet keeping the beer lines cold. This first line would be considered the supply side of the forced air loop.

Once the air has reached the beer tower, it returns to the cooler through the other section of tubing called the return. The supply and return create an infinite loop of forced air to maintain the temperature of the beer trunk line(s).

How Effective is a Forced Air System?

The effectiveness of this type of system, whether it’s a single or dual duct setup, will be the refrigeration temperature. Your foodservice design company or refrigeration engineer will need to factor in the standard design criteria for a walk-in cooler, the air ducts’ length, and the heat generated from the blower.

For this setup to be successful, the walk-in cooler for beer storage must maintain a consistent temperature of 34-38F. The maximum recommend length for this setup is 25 ft. requiring approximately 1,000 Btu per hour of additional refrigeration capacity. The system can exceed 25 ft., but you would need to minimize the amount of 90-degree bends in the system and make sure the walk-in cooler is not frequently opened. Each 90-degree bend in the system will result in lost cooling efficiency.

If you plan on frequently accessing the cooler (i.e., produce cooler), this system will not work effectively for you because the air will warm up and cause pouring issues.

Key Tips:

- Properly size the blower to deliver the proper amount of CFMs.

- Limit the number of 90-degree bends in the air duct(s).

- Seal all seams to reduce air leaks through the duct(s).

- Secure all beer connections to prevent air leaks or cooling loss.

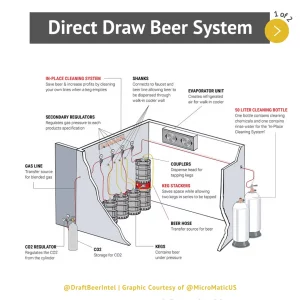

Type 3: The Direct Draw Beer System (Short-Draw)

This is the most common and straightforward draft beer system for delivering draft beer from keg to tap across a short distance. It is the top choice for bars with a beer keg located within a few feet of the beer dispensing faucet. Most commercial keg boxes, refrigerator conversions, and home bars are configured with direct draw systems.

This type of direct draw beer system is another less expensive option to glycol chilling, and it also has the added benefit of minimal beer waste due to the short length of the beer lines. The cost of a direct draw beer system will vary depending on the size of the equipment (kegerator vs. walk-in cooler box), the number of beer lines, and the overall quality of the installation.

The Components For A Direct Draw Beer System

- COOLER

- CO2 Tank

- Primary Regulator

- Air Line

- Secondary Regulator

- Keg Coupler

- TRUNKLINE

- Beer lines

- BEER TOWER

- Draft faucet

- Tap handle

- Drip tray

How It Works

A direct draw beer system may be housed in a walk-in cooler, a kegerator, or a converted refrigerator under the counter.

These draft beer systems will have the faucet directly connected to either a cooler box or a tower directly connected to a self-contain cooler. The beer kegs are stored, cooled, and tapped in the same cooler. The beer in the keg, beer line, and beer tower connected to the faucet is chilled by circulated cold air. A thermostat regulates this self-contained refrigeration unit, which keeps the stored kegs between 34- 38 ° F for optimum performance.

Self-Contained Keg Storage and Dispensing (Kegerator):

The kegerator uses a forced cold air supply to the draft towers to maintain consistent temperature from the box to the faucets. And the kegerator box is controlled by a thermostat that should maintain a constant temperature of 34-38F. The kegerator offers several benefits, but the main downside is limited keg storage.

For some applications where space is a problem, a kegerator can be combined with a remote refrigeration unit to increase the keg storage space.

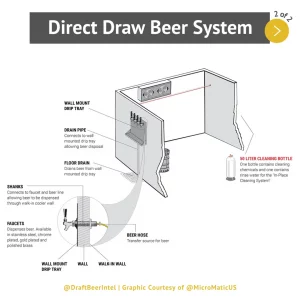

Walk-in Cooler System (Dispensing directly through the wall):

The walk-in cooler stores both the kegs and beer lines to deliver product(s) to the shanks directly mounted through the cooler wall. A wall mount drip tray is installed on the outside wall of the cooler to contain any spillage that occurs during the pouring process. The beer should pour at the same temperature stored in the walk-in cooler if properly installed.

How Effective is Direct Draw System:

This system can be highly effective and profitable if properly designed and maintained due to its straightforward dispensing. The direct draw system offers the benefits of no hidden beer lines to make service and access easier. Due to the short length of the beer lines, there is a lot less waste during the cleaning process.

Key Tips:

- Make sure the walk-in is dedicated to keg beer. You want to minimize the amount of foot traffic to maintain keg temperatures.

- Keep wall thickness to a minimum to prevent the shanks from warming up inside the wall.

- You can use longer shanks to expose more surface area to the cooler to help conduct more cold to the faucet.

- Calculate ROI on the cost of your kegs (1/2 vs. 1/6) and the number of flavor options you’d like to offer your customers. Sometimes less will be more when it comes to your profit margins.

Which Type Of Draft Beer System Should You Choose?

To sum up everything above, your decision of which draft beer system to use depends on a few things:

- What is your current beer dispensing setup?

- How far your beer keg is from the dispenser?

- How many beers and different styles of beer are you planning to have?

- What is your overall project budget?

- What is your overall goal?

If you run a small bar or want to enjoy a fresh, cold beer at home once in a while, you should go with a kegerator or short-draw draft system. It’s easy to use, and it’s affordable.

If you own a full-sized pub or restaurant with a walk-in cooler that’s more than 25 feet away from the beer tower, installing a long-draw draft beer system with a glycol power pack is best.

Cheers to you for learning about the three types of draft beer systems!

Here at Draft Beer Intelligence, we always want to help you deliver the perfect pour day after day. And to make sure that your draft beer systems produce GREAT tasting beer and MAXIMIZE profits!

Contact us here anytime if you need a draft beer system design, installation, ongoing maintenance, or service nationwide. Together, let’s keep “DOING BEER JUSTICE!”

Check out our other similar posts:

How To Clean Your Draft Beer Lines and Faucets

Why Proper Draft Beer Line Cleaning Is So Important

Choosing Faucets For Your Draft System (Stainless vs. Brass)

How Clean Is Your Draft Beer System (Cleaning Recommendations Included)

The Dirty Secret You Don’t Know About Draft Beer Line Cleaning Regulations