Draft beer faucets are used to serve draft beer. They come in various shapes, sizes, and types, including pourers, stout faucets, forward-sealing faucets, and many more.

Understanding how these faucets work is essential to enjoy a cold brew at home or in a bar/restaurant.

In this blog post, we answer all your beer faucet questions and more. Here is our guide to draft beer faucets.

What is a Draft Beer Faucet?

The faucet is the dispensing point for the beer, and it is attached to the beer shank. A beer handle attaches to the faucet, which opens and closes the faucet to allow beer flow. A shank connects the faucet to the beer line and is attached to the wall or beer tower.

Types of Draft Beer Faucets

Chrome-Plated Beer Faucets:

Chrome-plated faucets are, unfortunately, the most common style of faucets you will find at most restaurants and bars. They have slowly become the industry standard. They are less expensive and function the same way as stainless steel. The chrome plating finish doesn’t withstand the wear and tear of long-term continuous use. The shiny chrome finish is visually attractive and stands out behind any bar.

After several months of use and exposure to the beer’s acidity and various cleaning agents, a standard chrome-plated faucet will corrode and impart unwelcome flavors to your beverage.

If you build a kegerator for your home or a draft system that won’t require frequent use, chrome-plated faucets are still feasible. Make sure you monitor the level of wear over time and replace it at the first exposure of brass.

Stainless Steel Beer Faucets:

Stainless steel faucets are a significant upgrade over the standard chrome-plated brass option, and they are also a standard design spec for all Draft Beer Intelligence installations.

The added value of having a stainless steel faucet that will last for many years behind your bar balances the trade-off of the additional cost. If you replace your chrome faucets at the first sign of brass exposure, you can go through several chrome faucets over the life span of one stainless steel faucet.

Stainless steel is less susceptible to corrosion. It is also a sanitary option because it is more resistant to the formation of bacteria and other organic build-up.

Therefore, stainless steel should be a must if you want to dispense cocktails on tap, wine on tap, coffee on tap, or kombucha on tap. The acidity in these beverages will almost immediately erode the finish of a plated-brass faucet and cause whatever winds up in your glass to become undrinkable.

At DBI, we understand that the industry is constantly changing; one-week draft cocktails are hot, and then the next week, wine on tap sounds good. We design and build our systems to accommodate these changes without additional costs from our customers, which is another reason we lean on stainless steel faucets and fittings.

Read more about why we always recommend stainless faucets in our blog post: Choosing Faucets For Your Draft System

Polished Brass Beer Faucets:

There are options if you want the look of polished PVD brass for your faucets. A polished brass draft beer faucet delivers the same affordability and functionality as the standard chrome-plated faucet.

There is an option to purchase a stainless steel faucet with a tarnish-free brass PVD finish. This type of faucet has brass on the outside but with the durability of stainless steel on the inside.

Parts of a Draft Beer Faucet

The parts of a draft beer faucet include a handle (or lever), an outlet tube (where the beer flows through), and an air intake valve (which regulates the flow rate).

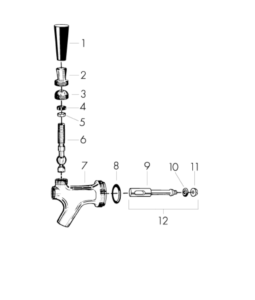

Here’s a breakdown of the parts of a Stainless-Steel Beer Faucet:

- Tap Handle

- Faucet Collar

- Faucet Bonnet

- Friction Washer

- Ball Washer

- Faucet Lever

- Faucet Body

- Faucet Coupling Washer

- Faucet Shaft

- Faucet Seat Washer

- Faucet Shaft Nut

- Faucet Shaft Assembly

How to Clean a Draft Beer Faucet

Faucet hygiene is critical to the operation of your draft beer system. It’s the final point of draft beer system dispensing, and the faucet is almost always visible to your customer.

Several types of beer faucets are available that require specific cleaning methods. To maintain a clean, sanitary beer faucet, they should be completely disassembled, chemically soaked, and scrubbed every two (2) weeks.

We recommend retailers rinse faucets with fresh water at closing daily. This daily routine will keep your beer faucets and lines cleaner.

The other benefit is that beer becomes sticky, like glue, as it dries out. The daily rinsing will prevent this, and your pours will always be easier, which means you won’t need to crank on a beer handle on your first and second pour.

There are also faucet plugs that insert into or cover the beer faucet opening when beer is not pouring.

We suggest the beer plugs that insert into the faucet because they are more sanitary and easier to clean. The plugs that cover the beer faucet are much harder to clean and maintain. These simple steps will help keep your beer faucets cleaner and more sanitary.

Draft Beer Faucet Troubleshooting

If you’re experiencing issues such as cloudy beer, foamy beer, slow pour rate, restricted beer flow, or problems with your CO2 system, then it’s important to troubleshoot the problem using a few simple steps.

- Check that the faucet is tightened correctly onto the shank and there are no visible leaks.

- Make sure the keg coupler is properly connected to the beer keg.

- Inspect all parts of the draft system for any build-up of dirt or grime.

- Check all connections for leaks to ensure everything is functioning correctly.

- Ensure the gas portion of your draft beer system is on all gas tanks full. If you run a nitrogen generator, make sure its plugged in and operational.

Draft beer faucets are essential for ensuring that your beer tastes its best. Keeping them clean and properly maintained will help ensure you get the most out of your draft beer experience. You can easily clean and troubleshoot any problems with your draft beer faucet with a few simple steps!

Happy Pouring!

Here at Draft Beer Intelligence, we always want to help you deliver the perfect pour daily. And to make sure that your draft beer systems produce GREAT-tasting beer and MAXIMIZE profits!

Remember, proper system maintenance is crucial to ensure fresh and high-quality beer. You will indeed have happy patrons or satisfied friends by monitoring the system’s temperature, pressure, and cleanliness.

Contact us anytime if you need draft beer or beverage system design, installation, ongoing maintenance, or service nationwide. Together, let’s keep “DOING BEER JUSTICE!”