DBI Project Details:

-

PROJECT: Draft Beer System Installation

-

CLIENT: The Back Abbey

-

LOCATION: Upland, CA

-

SERVICES: Draft Beer System, Glycol Power Pack Installation, Custom Beer Tower

Everything was installed per the DBI standard (aka the highest quality)…This means that we used the best stainless steel parts, components, and barrier tubing.

We were so excited to build a custom system for a restaurant that offers such a unique selection of Belgian beers.

Engineering and designing a system that delivers the beers like the brewer intended was a must for The Back Abbey, and we’re so grateful they thought of us first! (Also, thank you to Jessica at Global Beer for always introducing and recommending us to their awesome customers)!

Here are some photos from the installation:

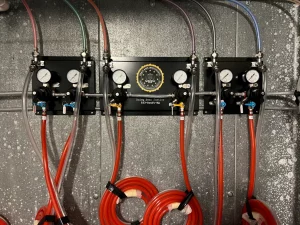

DBI Custom Secondary Regulator Panels & Trunkline

Our custom panels include all stainless steel components, and for this installation, we use an upgraded smaller diameter Micromatic Barriermaster Flavourlock trunkline that has an exceptional gas barrier layer along with outstanding hygienic quality.

And the Barriermaster Flavourlock beer trunkline is ideal for protection against cross migration of flavors.

The Beer Tower

We installed a custom beer tower with Perlick stainless steel beer faucets.

As always, the tower installation includes all stainless steel components and barrier tubing.

Glycol Power Pack

And lastly, we installed a Micromatic glycol power pack to keep the beer cold from the walk-in cooler to the beer tower. We hope you cheers you over at The Back Abbey soon!

Do you have a project of your own that you need support with?

Here at Draft Beer Intelligence, we always want to help you deliver the perfect pour day after day. And to make sure that your draft beer systems produce GREAT tasting beer and MAXIMIZE profits!

Contact us here anytime if you need draft beer system design, installation, ongoing maintenance, or nationwide service. Together, let’s keep “DOING BEER JUSTICE!”